Since our inception, we have been committed to providing automatic excellence in road construction equipment. Our wet mix macadam plant is one such product that is the result of the outstanding engineering skills of our experts. The machine is developed to help our clients obtain a homogenous mix of materials to make base and sub-base in road-building projects.

The wet mix macadam plants are manufactured considering their use in the most challenging job site requirements. The configuration and features assure reliability and minimal downtime. Our product is made of durable components with high precision.

Coninfra Machinery offers custom solutions from 100 TPH to 300 TPH to fulfill the individual construction requirements of our clients. In addition, We Supply a Cement Treated Sub Base (CTSB) and other accessories with the wet mix macadam plant to make it more adaptable and versatile.

Our wet mix plant has varying operational capacities to provide optimum performance and cost-efficiency. Implementation of advanced technology in our equipment helped us deliver custom solutions according to the unique foundation drawing supplied by a client.

State-of-the-art technology also ensures lower operating costs, durability, and high efficiency.

Our wet mix macadam plant has been created following stringent measures such as MORTH specifications to ensure performance at the optimum rate. The machine is user-friendly while capable of delivering a high production rate. Using proper aggregate and additives feeder, our plants yield a high-quality mix.

| MODEL | CPMPL-100 | CPMPL-150 | CPMPL-200 | CPMPL-250 | CPMPL-300 |

|---|---|---|---|---|---|

| CAPACITY | 100 TPH | 150 TPH | 200 TPH | 250 TPH | 300 TPH |

Standard Configuration

Pugmill Mixing Unit

It comprises:

- A heavy-duty low-speed pug mill type mixer with steel casting paddles

- Replaceable and adjustable Ni-Hard tips

- Replaceable Ni-Hard liner plates

Coninfra’s twin shaft pug mill configuration delivers quick, uninterrupted, and homogenous mixing of additives and aggregates. The extra heavy-duty anti-friction bearings are mounted with shafts providing hassle-free operation and increased lifespan.

In addition, the pug mill unit of the wet mix macadam plant consists of 100mm Ni-Hard replaceable tiles lined on the inside. The liners on the inner shell and side plate are responsible for resistance against wear and tear and increased life of the pug mill. This component is developed to ensure it can withstand an overload of 20% in continuous operation without compromising the quality of the mix.

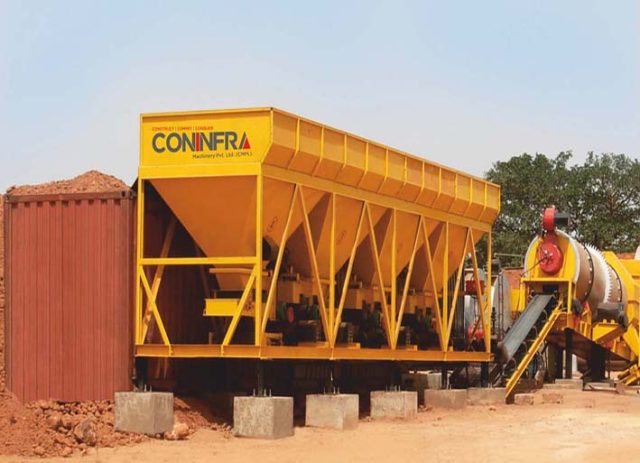

Cold Aggregate Four Bin Feeder

Coninfra manufactures high-quality bins that are all-welded and modular in construction. This allows our customers to easily add more bins to satisfy the extending requirements of any project. Aggregates flow freely from the feeders using steep bin walls and valley angels. It makes sure that the materials are not stuck in the corners due to sticky aggregates.

The bins comprise adaptable calibrated gate openings and variable speed feeders that work together to deliver increased flexibility, 100% proportional control, and accuracy in operations.

Paddle Arms & Tips

Our pug mill paddle arms and tips feature a heavy-duty design that helps obtain a homogenous mix, especially the Ni-hard tips. This ensures it can withstand wear and tear, thereby reducing the operational cost of the wet mix macadam plant.

Conveyors - Load out & Slinger

Coninfra Machinery supplies slinger conveyor, load-out conveyor with gob hopper, and power pack.

Pugmill

Inside view of Pugmill

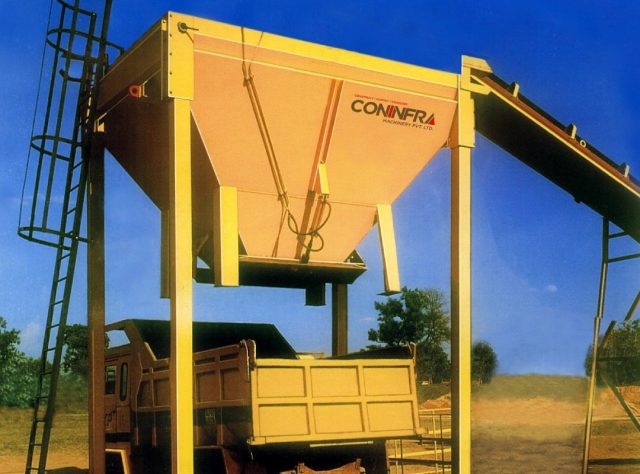

Silo

Electrical Control Panel With Fully Furnished Cabin

Wet mix macadam plants have a control system with function and numeric keys. Hence, operating the unit does not require special skills or training. Our wet mix plant combines an entirely automated control cabin with an electrical power control console. You get to leverage a completely automatic process in all our plants. An easy-to-navigate software is highly reliable and high performing. Other features include

Fail proof interlocks and auto process controls

Online fault detection

Online printing facility

Provisions to print, store and edit production details, mix proportions, etc.

Display of all process control parameters

Automatic, semi-automatic & manual operation

Storage Silo (Optional)

As an option, we offer a 25 MT storage silo that is strong and easy to use and transfer. There is minimal mix segregation due to the batcher arrangement at the feeding point. Hydraulically handled clamshell gates support the fast discharge of mixed material into the trucks without any issue of segregation.

Water Tank (Optional)

MT is provided with one or two water tanks manufactured from steel plates with manhole, pump, flowmeter, and more.

Installations Around the World

Technical Information

| CMPL -100(100 TPH) | CMPL -150(150 TPH) | CMPL -200(200 TPH) | CMPL -250(250 TPH) | |

|---|---|---|---|---|

| Four Bin Feeder | ||||

| Storage Capacity | 20 M3 (31 MT) | 20 M3 (31 MT) | 25 M3 (40 MT) | 25 M3 (40 MT) |

| Auxiliar Conveyer | 400 mm ×2.2 mtr × 4 ply | 400 mm ×2.2 mtr × 4 ply | 400 mm ×2.92 mtr × 4 ply | 400 mm ×2.92 mtr × 4 ply |

| Conneted Load | 0.75 KW × 4 Nos | 0.75 KW × 4 Nos | 1.5 KW × 4 Nos | 1.5 KW × 4 Nos |

| Gathering Conveyer | 500 mm × 22.5 mtr | 500 mm × 22.5 mtr | 600 mm × 25.6 mtr | 600 mm × 25.6 mtr |

| Bin Vibrator | 0.75 KW | 0.75 KW | 0.75 KW | 0.75 KW |

| Gathering Connected Load | 3.70 KW | 3.70 KW | 5.50 KW | 5.50 KW |

| Shipping Dimension | 12.5 × 2.25 × 2.45m | 12.5 × 2.25 × 2.45m | 13.5 × 2.25 × 2.45m | 13.5 × 2.25 × 2.45m |

| Vibrating Screen | ||||

| Dimension | 1350 mm × 1350 mm | 1350 mm × 1350 mm | 1350 mm × 1350 mm | 1350 mm × 1350 mm |

| Screening Area | 900 mm × 1200 mm | 900 mm × 1200 mm | 900 mm × 1200 mm | 900 mm × 1200 mm |

| Connected Load | 0.75 KW | 0.75 KW | 0.75 KW | 0.75 KW |

| Slinger Conveyor | ||||

| Conveyor Belt | 600mm × 15 mtr | 600mm × 15 mtr | 600mm × 15 mtr | 600mm × 15 mtr |

| Conveyor Drive Motor | 3.70 KW | 3.70 KW | 3.70 KW | 3.70 KW |

| Pug Mill | ||||

| Capacity | 100 TPH | 150 TPH | 200 TPH | 250 TPH |

| No.of Arms | 28 | 32 | 64 | 78 |

| Connected Load | 18.50 KW | 22.00 KW | 30.00 KW | 37.50 KW |

| Shipping Dimension | 1400 × 2550 × 3200mm | 3950 × 1580 × 3000mm | 1400 × 2550 × 3200mm | 1400 × 2550 × 3200mm |

| Mydraulic Power Pack | ||||

| Connected Load | 2.2 KW | 2.20 KW | 2.20 KW | 3.70 KW |

| Load Out Conveyor | ||||

| Load out Conveyer | 600mm × 17.9 | 600mm × 17.9 | 600mm × 17.9 | 800mm × 20.3 |

| Conveyor Drive Motor | 5.50 KW | 5.50 KW | 5.50 KW | 7.50 KW |

| Water Tank (Optional) | ||||

| Capacity | 12000 Ltrs. | 15000 Ltrs. | 15000 Ltrs. | 20000 Ltrs. |

| Water Pump | ||||

| Connected Load | 1.5 KW | 1.5 KW | 1.5 KW | 2.2 KW |

| 25 Mt Storage Silo (Optional) | ||||

| Shipping Dimension | 4140 × 2980 × 3000mm | |||

| 40 Mt Filler Silo (Optional) | ||||

| Connected Load | 4.45 KW | |||

| Shipping Dimension | 2420 × 10600mm | |||

| Cabin | ||||

| Fully Furnished | 8 × 6 Feet | |||

Frequently Asked Questions About Our Wet Mix Macadam Plants

A Wet Mix Macadam Plant is a type of construction equipment designed to produce a mixture of aggregates, water, and binder (usually bitumen) to create a stable base or sub-base layer for road construction. This mixture, known as wet mix macadam (WMM), provides a solid foundation to withstand heavy traffic loads and adverse weather conditions. The plant typically consists of components like aggregate feeders, conveyor belts, pugmill mixer, water tank, and control panel, working together to blend the materials and produce the wet mix laid and compacted on the construction site.

A Wet Mix Macadam Plant (WMM plant) operates by blending various aggregates, water, and binder to create wet mix macadam (WMM), a durable material used in road construction. Aggregates are fed into the plant’s pugmill mixer, combined with water and binder, typically bitumen. This mixture is carefully controlled using a water tank to achieve the desired moisture content. The pugmill mixer ensures a consistent and uniform blend. The resulting wet mix is then transported via conveyor belts to construction trucks or storage areas. At the construction site, the wet mix macadam is laid and compacted to create a strong base layer. This process ensures high-quality road construction with efficient WMM plant working.

When using a Wet Mix Macadam Plant, prioritize safety measures to protect workers and ensure smooth operations. Proper training and competency of personnel, along with the use of personal protective equipment (PPE), are essential. Limit access to authorized personnel only and have accessible emergency stop buttons. Establish lockout/tagout procedures for maintenance, ensure proper lighting, and mark hazardous areas clearly. Implement fire prevention measures, adhere to electrical safety guidelines, and store materials appropriately. Develop and enforce safe operating procedures, conduct regular maintenance, and maintain a well-equipped first aid kit. Have an emergency response plan in place, designate a supervisor for oversight, and cultivate a safety-oriented culture.

A Wet Mix Macadam Plant comprises key components: aggregate feeders for materials, a pugmill mixer for thorough mixing with water and binder (like bitumen), a water tank for precise moisture, conveyor belts for seamless material transport, and a control panel for operation monitoring. This plant creates a uniform wet mix of macadam, vital for solid road bases.

A Wet Mix Macadam Plant (WMM plant) offers many benefits in road construction. It ensures a robust base layer for roads and pavements, maintaining stability. Precise mixing ensures uniform aggregates and binders, enhancing consistency. Tailored mixtures cater to specific project needs, optimizing performance. Reduced dust emission in production creates a cleaner environment. The resulting wet mix macadam supports heavy traffic with load-bearing solid capacity. Efficient production and quick on-site laying accelerate project completion, enhancing cost-effectiveness. Controlled resources and mixtures ensure high-quality results that meet standards, bolstering road quality. Versatile beyond roads, WMM in road construction aligns with sustainability goals, combining efficiency with environmental consciousness.

Our Latest Articles

Why Hydraulic Broomers Are Essential for Modern Road Cleaning

How to Maintain Your Asphalt Drum Mix Plant for Long-Term Use

The Top Features to Look for in a Bitumen Sprayer Machine

Reach out to Coninfra to receive innovative solutions for your business

+91 90999 41311

Social media