Key Features

Powered with Kirloskar / Ashok Leyland Engine

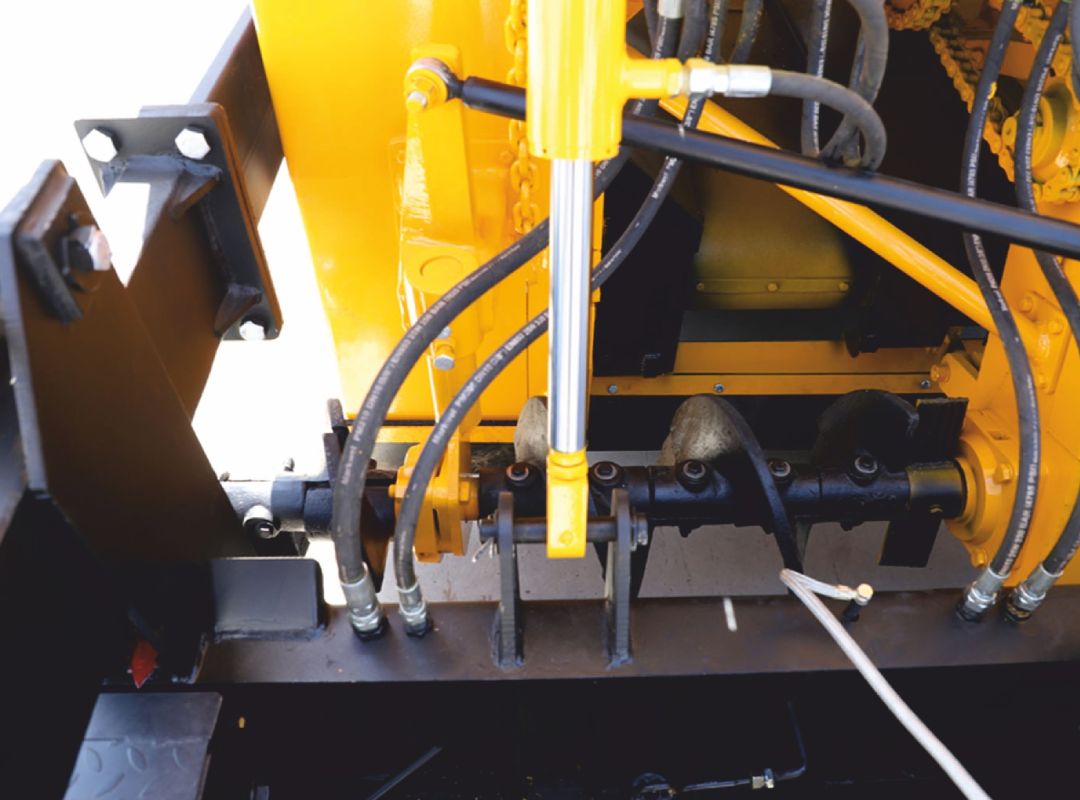

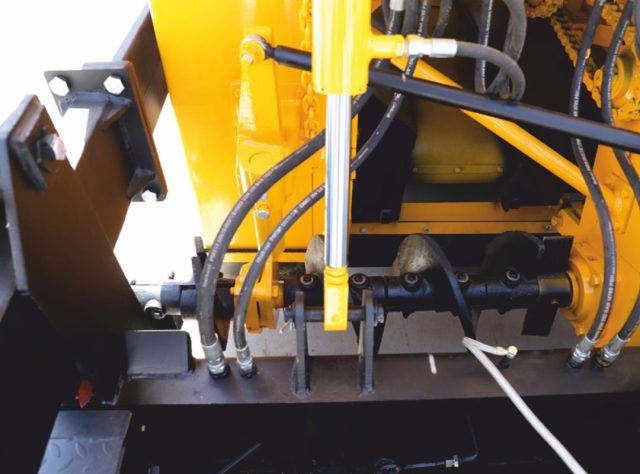

Hydraulic Cylinder Tafe / Dental

Stearing Unit Sauer Danfoss

Auger Diameter – 300 mm (Ni – hard material)blanchir coque telephoneshein phone casesel barco de los niñostelefoonhoesjes se 2020see here now

Screed Plate of $5 / Hardox 400

Tyre CEAT / Apollo, Battery Exide / Prestolite

Brife Description

| SR. NO | MODEL | ENGINE | PAVING WIDTH | SCREED |

|---|---|---|---|---|

| 01 | CMPL-SP550 | Kirloskar 6RI080TA1 125 HP/ ASHOK LEYLAND 125 HP | 2.5t0 4.5 m Dual Applicable (Upto 5.75 m With Extension) |

Hydraulically Extendable Temping & Vibrating Screed |

| 02 | CMPL-WP450 (HES) |

Kirloskar TURBO 105 HP/ ASHOK LEYLAND 101 HP. |

2.5 to 4.5 m Dual Applicable (Upto 5 m With Extension) |

Hydraulically Extendable Vibratory Screed |

| 03 | CMPL-AP450 (HES) |

Kirloskar 76 HP (Upto 5 m With Extension) |

25t045m | Hydraulically Extendable Vibratory Screed |

| 04 | CMPL-WP450 (STD) |

Kirloskar TURBO 105 HP/ ASHOK LEYLAND 101 HP. |

2.5 to 4.5 m Dual Applicable | Mechanical Screed (Bolted Extension From 75 mm to 300 mm) |

Installations Around the World

Technical Specifications

| TRACTOR | |

|---|---|

| Operating Height | 3.43 m |

| Shipping Height | 2.52 m |

| Height w/o Canopy | 2.52 m |

| Length | 6.61 m |

| Operating Width | 3.14 m |

| Shipping Width | 2.54 m |

| Tread Width | 2.08 m |

| Truck Dumping Clearance | 0.48 m |

| Wheel Base | 2.61 m |

| Frame Plate Thickness | 16 mm |

| PRIME MOVER | ||

|---|---|---|

| Engine Make | kirloskar | Ashok Leyland |

| Model No. | 6R1080TA1 | H6ETIC3RU23 |

| Engine Power | 92kW @ 2300 rpm | 99kW @ 2300 rpm |

| Length | 6.61 m | |

| Electrical System | 12 VDC | |

| Type of Cooling | Water Cooled | |

| WHEELS | |

|---|---|

| Tyre Front Solid | 4 nos / 22 × 16 × 12 |

| Tyre Rear Pneumatic | 4 nos / 10.00 × 20 |

| PERFORMANCE | |

|---|---|

| Weight | 14840 kg |

| Turning Radius Inner | 5.5 m |

| Laying Capacity | 300 TPH |

| Paying Thickness | 10 -300 mm |

| Paving Speed | 0 – 40 m/min |

| Paving Speed(Second) | 0 – 15 km/hr |

| Hopper Capacity (Approx.) | 10t |

| CONTROL | |

|---|---|

| Operating Station | Dual Station |

| Brake | Kaliper Disk Brake |

| FEEDERS | |

|---|---|

| Auger | Highly wear resisting steel casting dia. 355 mm 20 mm thickness |

| Feed Tunnel Width | 590 mm |

| Conveyor Floor Plate | Wear resisting steel 12 mm |

| Feed Control System | 2nos. on/off Type |

| Auger Control System | 2nos. on/off Type |

| Auger Lowest Position | 150 mm |

| From Ground | |

| Auger and Conveyor Drive | Syncronised |

| SCREED | TV 4500 |

|---|---|

| Screed Basic Width | 250 m |

| Infinite Variable Extension | 2.50 m tO 4.50 m |

| With Bolt On Extension Max | 5.75 m |

| Screed Weight Main | 2890 kg |

| Bolt On Extension Weight | 210 kg (625 mm) |

| Crown | -1 to +4.5% |

| Gradient Slope | 10% Gradient Slope |

| Screed Vibration | 30-50 Hz |

| Tamping | 18-27 Hz (5 mm) |

| Screed Plate | 320 mm x 12 mm Wear Resistant |

| Screed Heaters | 40s Diese (Propane Optional) |

| Foot Rest |

| SENSOR DEVICE | |

|---|---|

| Grade and Slope Control | Moba Controls |

| Power Output | on/off Type |

| Grade control measuring range | (+_) 70 mm |

| Obtainable accurancy for grade | (+_) 1 mm |

| Stop contol measuring range | (+_) 10% |

| Stop contol measuring Slope | (+_) 0.05% |

| Enclosure Protection | I P54 |

| Safety Devices | in built pressure relief valves |

| Make / Type Of Pumps and Motors | Sauer Danfoss or Equivalent |

| CAPACITY | |

|---|---|

| Fuel Tank Capacity | 132 Ltr. |

| Hydraulic Tank Capacity | 190 Ltr. |

| TRACTOR | |

|---|---|

| Operating Height | 3.43 m |

| Shipping Height | 2.52 m |

| Height w/o Canopy | 2.52 m |

| Length | 6.61 m |

| Operating Width | 3.14 m |

| Shipping Width | 2.54 m |

| Tread Width | 2.08 m |

| Truck Dumping Clearance | 0.48 m |

| Wheel Base | 2.61 m |

| Frame Plate Thickness | 16 mm |

| PRIME MOVER | ||

|---|---|---|

| Engine Make | kirloskar | Ashok Leyland |

| Model No. | 6R1080TA1 | H6ETIC3RU23 |

| Engine Power | 92kW @ 2300 rpm | 99kW @ 2300 rpm |

| Length | 6.61 m | |

| Electrical System | 12 VDC | |

| Type of Cooling | Water Cooled | |

| WHEELS | |

|---|---|

| Tyre Front Solid | 4 nos / 22 × 16 × 12 |

| Tyre Rear Pneumatic | 4 nos / 10.00 × 20 |

| PERFORMANCE | |

|---|---|

| Weight | 14840 kg |

| Turning Radius Inner | 5.5 m |

| Laying Capacity | 300 TPH |

| Paying Thickness | 10 -300 mm |

| Paving Speed | 0 – 40 m/min |

| Paving Speed(Second) | 0 – 15 km/hr |

| Hopper Capacity (Approx.) | 10t |

| CAPACITY | |

|---|---|

| Fuel Tank Capacity | 132 Ltr. |

| Hydraulic Tank Capacity | 190 Ltr. |

| CONTROL | |

|---|---|

| Operating Station | Dual Station |

| Brake | Kaliper Disk Brake |

| FEEDERS | |

|---|---|

| Auger | Highly wear resisting steel casting dia. 355 mm 20 mm thickness |

| Feed Tunnel Width | 590 mm |

| Conveyor Floor Plate | Wear resisting steel 12 mm |

| Feed Control System | 2nos. on/off Type |

| Auger Control System | 2nos. on/off Type |

| Auger Lowest Position | 150 mm |

| From Ground | |

| Auger and Conveyor Drive | Syncronised |

| SCREED | TV 4500 |

|---|---|

| Screed Basic Width | 250 m |

| Infinite Variable Extension | 2.50 m tO 4.50 m |

| With Bolt On Extension Max | 5.75 m |

| Screed Weight Main | 2890 kg |

| Bolt On Extension Weight | 210 kg (625 mm) |

| Crown | -1 to +4.5% |

| Gradient Slope | 10% Gradient Slope |

| Screed Vibration | 30-50 Hz |

| Tamping | 18-27 Hz (5 mm) |

| Screed Plate | 320 mm x 12 mm Wear Resistant |

| Screed Heaters | 40s Diese (Propane Optional) |

| Foot Rest |

| SENSOR DEVICE | |

|---|---|

| Grade and Slope Control | Moba Controls |

| Power Output | on/off Type |

| Grade control measuring range | (+_) 70 mm |

| Obtainable accurancy for grade | (+_) 1 mm |

| Stop contol measuring range | (+_) 10% |

| Stop contol measuring Slope | (+_) 0.05% |

| Enclosure Protection | I P54 |

| Safety Devices | in built pressure relief valves |

| Make / Type Of Pumps and Motors | Sauer Danfoss or Equivalent |

Frequently Asked Questions About Our Sensor Paver Finisher

The Sensor Paver Finisher by Coninfra Machinery Pvt Ltd is a highly sophisticated machine with many paving features and other surface finishing operations. It boasts a smooth, adjustable speed of up to 40 m/min – allowing for precise operation in different types of terrain. The advanced sensor technology allows the operator to precisely control the depth, slope and level of the pavement being laid – enabling an even, consistent finish every time. The Sensor Paver Finisher also has a powerful hydraulic system that ensures smooth operation and helps to reduce wear and tear on the machine. Additionally, it is equipped with a state-of-the-art anti-skid system for additional safety when operating in wet conditions.

The Sensor Paver Finisher by Coninfra Machinery Pvt Ltd is versatile and well-suited for many road construction projects. It excels in paving various types of roads, including highways, city streets, rural roads, and airport runways. Moreover, it proves effective on surfaces like asphalt and concrete, making it adaptable for different paving applications. Coninfra’s Sensor Paver Finisher showcases its ability to cater to diverse road construction needs with precision and efficiency.

Regular maintenance is essential for the optimal performance and longevity of the Sensor Paver Finisher by Coninfra Machinery Pvt Ltd, a trusted Sensor Paver Finisher Manufacturer in India. Scheduled maintenance routines, including inspections, lubrication, cleaning, and parts replacement as needed, ensure that the machine operates at its best and minimizes the risk of unexpected breakdowns. Following the manufacturer’s recommended maintenance guidelines is crucial to ensure consistent and reliable performance over time.

The Sensor Paver Finisher by Coninfra Machinery Pvt Ltd is designed to be highly efficient, allowing the operator to quickly complete tasks with minimal effort. Its adjustable speed of up to 20 m/min enables a fast operation. At the same time, the advanced sensor technology ensures precise control of depth, slope and level in less time than other machines.

As a prominent Sensor Paver Finisher Manufacturer, Coninfra Machinery Pvt Ltd incorporates a host of safety measures into its equipment. These include emergency stop buttons, audible alarms, visual indicators, and protective guards to safeguard operator well-being. Furthermore, safety interlocks are in place to ensure that the machine operates safely only when all prerequisites are met. Coninfra’s commitment to safety and quality shines through in the Sensor Paver Finisher, showcasing its dedication as a reliable Sensor Paver Finisher Manufacturer.

Our Latest Articles

How to Maintain Your Asphalt Drum Mix Plant for Long-Term Use

The Top Features to Look for in a Bitumen Sprayer Machine

Top Features of a Modern Batch Mixing Plant You Should Know

Reach out to Coninfra to receive innovative solutions for your business

+91 90999 41311

Social media