| MODEL | CDMP-60 | CDMP-90 | CDMP-120 |

|---|---|---|---|

| CAPACITY | 40-60 TPH | 60-90 TPH | 90-120 TPH |

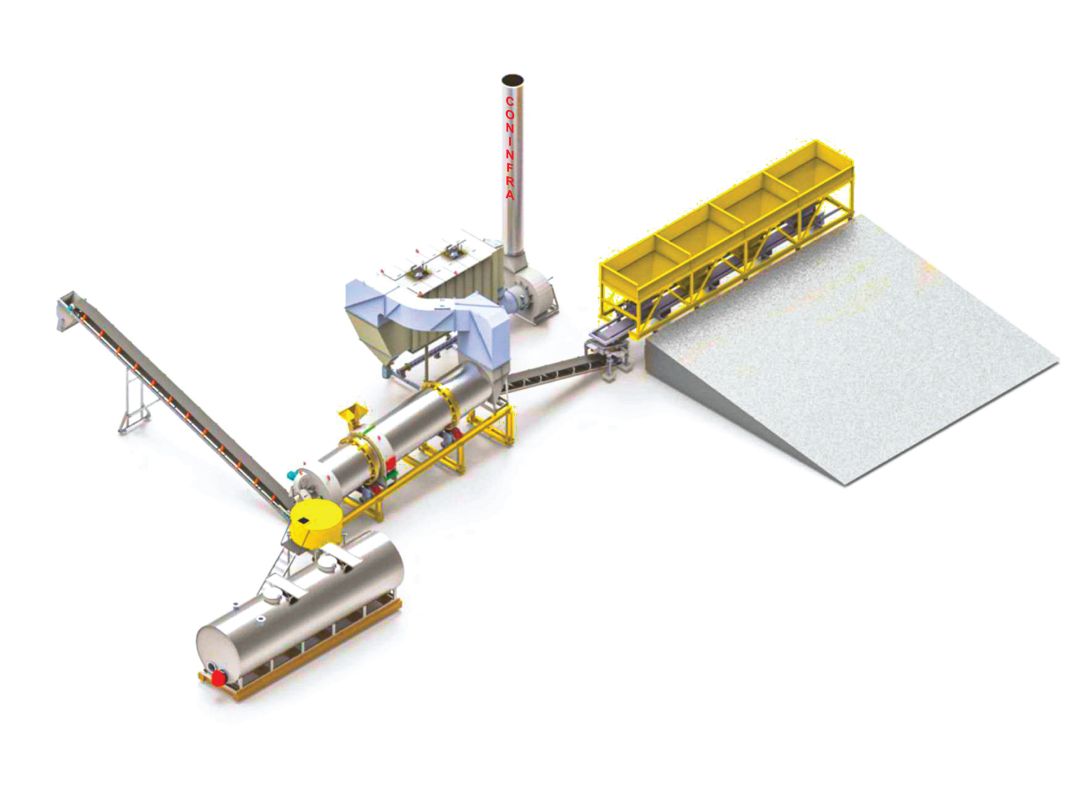

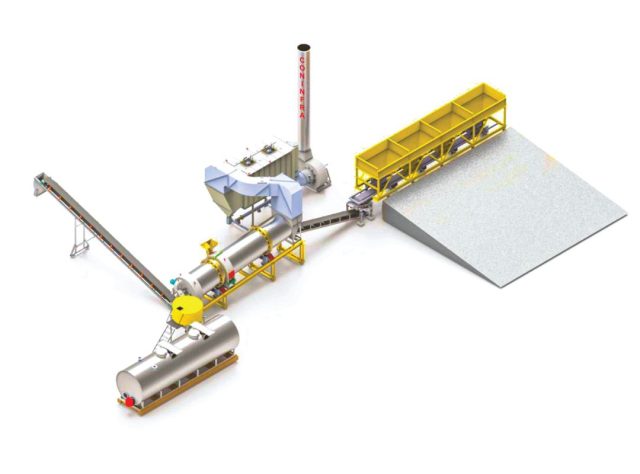

CDMP Series

Bitumen Storage and Heating Tank

The counterflow drum mix plant provides options from direct heating or hot oil-heated indirect heating systems. Storage tank capacities range from 15 to 50 tons.

Long Nose Burner

Highly fuel efficient modulating long nose burner suitable for diesel /LDO/FO as fuel.

Loadout Conveyor with Gob Hopper

Loadout conveyor with a gob hopper is the standard scope of supply. A hot mix storage silo is offered as a customized solution.

Recycling Solution

The counterflow dryer already has a rap collar as standard and can process up to 30% recycled material.

Counterflow Dryer

High-efficiency counter-flow dryer drum equipped with modulating long-nose burner. The drum of our counterflow asphalt plant gives high fuel efficiency with low emissions.

Baghouse Filter

Highly efficient reverse airflow cleaning baghouse filter with cascading type primary dust collector.

Four Bin Feeder

Modular Design four bin feeder with speed regulator technology as per operational requirement on each bin auxiliary belt. Bin vibrator fitted on dust feeder’s wall.

Advantages of Counter Flow Drum Mix Plant

Low Emission

High Fuel Efficiency

Produce High-Quality Asphalt Mix

Low Maintenance Easy to install

Easy to operate

High Production Rate

User Friendly

Scope Of Supply

- Cold Aggregate Feeder Bins (Four Bin Feeder)

- Single Deck Vibratory Screen for Oversized

- Material Removal

- Slinger Conveyor

- Counter Flow dryer drum with Dust Collector

- Dryer Auto Burner

- Load out Conveyor / Drag Slat Conveyor

- Bitumen Tank

- Mineral Filler Unit

- Centralized Control Panel with Control Cabin

- Fuel Storage Tank

- Pollution Control Unit (Bag Filter / Wet Scrubber)

- Storage Silo (Optional)

- Rap Feeding Arrangement (Optional)

Installations Around the World

Frequently Asked Questions About Our Counter Flow Drum Mix Plant

A Counter Flow Drum Mix Plant, engineered by Coninfra Machinery Pvt Ltd, is an advanced asphalt mixing plant. It features a unique design where aggregates and hot gases move in opposite directions, optimizing heating and mixing efficiency for superior asphalt production.

A Counter Flow Drum Mix Plant offers several advantages. The counter flow arrangement allows for better energy utilization, reduced emissions, improved temperature control, and higher fuel efficiency. This design enhances asphalt quality by minimizing overheating and ensuring uniform mixing.

For technical assistance with your Counter Flow Drum Mix Plant from Coninfra Machinery Pvt Ltd, reach out to our dedicated support team. We offer comprehensive technical support, troubleshooting guidance, and maintenance recommendations to ensure your plant’s smooth operation and productivity.

In a Counter Flow Drum Mix Plant, aggregates enter the drum from the opposite end of hot gases. As aggregates move towards the burner zone, they come in contact with hot gases, resulting in efficient drying and heating. This counter flow arrangement ensures thorough mixing and enhanced asphalt quality.

Coninfra Machinery Pvt Ltd’s Counter Flow Drum Mix Plant incorporates precision-engineered components, efficient drying and mixing zones, advanced burner technology, and user-friendly control systems. The plant is designed for high-performance, low maintenance, and optimal asphalt production.

Our Latest Articles

Construction Equipment Safety Standards: ISO, BIS & Site Compliance

Hot Mix vs Warm Mix Asphalt for Batch Plants Explained

How to Choose the Right Silo Manufacturing Company in India for Your Plant

Reach out to Coninfra to receive innovative solutions for your business

+91 90999 41311

Social media