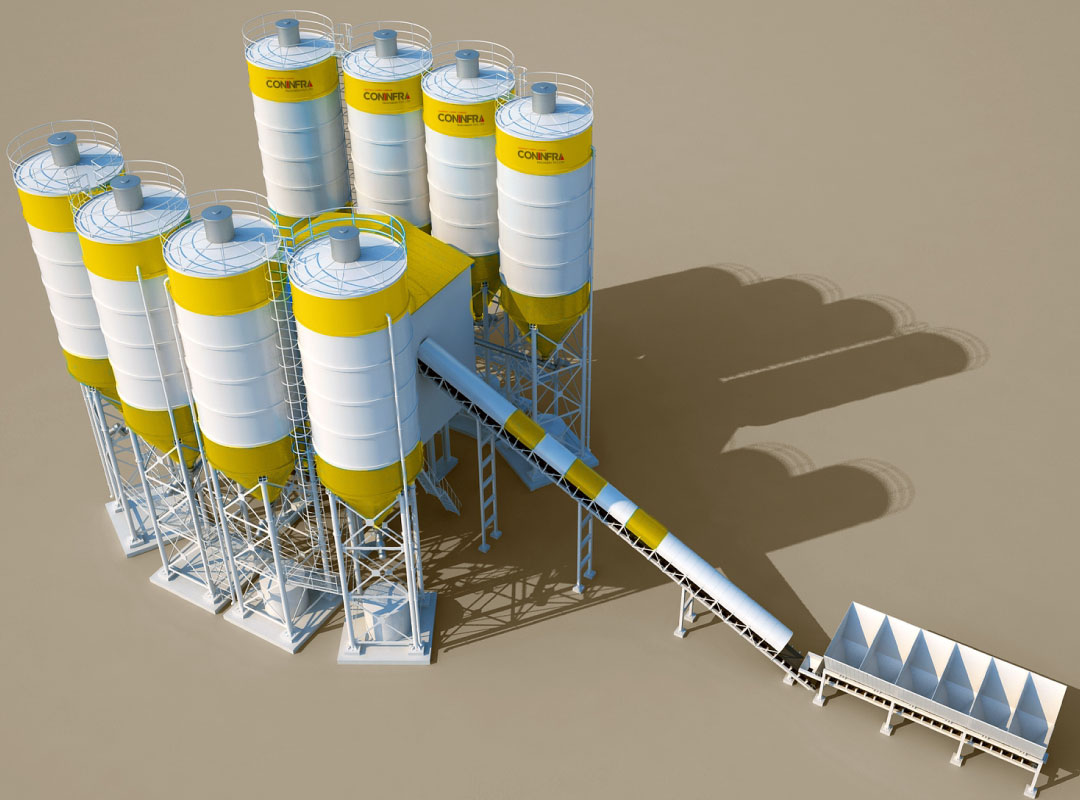

Standard Configuration

Three / Four Bin System

Load out Conveyors

Discharge Conveyor

Cement Hopper with Screw Conveyor

Cement Hopper with Screw Conveyor

High Pressure Jet Cleaner system for Mixer amazon phone casesd-brand phone caseself bar 600 περιπτεροelfbar 600handyhülle lederphone case near mephone case with strap

PLC + PC based Electrical Control Panel

Pan type Planetary Single Shaft Twin Shaft Mixer Type Mixing Unit

Aggregate Feeder

Four bin aggregate feeder comes built on a rugged structure. The open close mechanism of all the bin gates is by pneumatic cylinders. Each bin is provided with one/two open-close gates and vibratory motor(s) for quick and efficient materials discharge. Air compressor is provided with the feeder to power the pneumatics. Junction box holds all the controls of the feeder.

Weighing System

Cement weighing hopper is mounted on 3 load cells. A pneumatic operated butterfly valve is fitted for discharge. The cement weighing hopper is provided with pneumatic vibrator and two inlets for two screw conveyors. Water tank is supported on single load cell with pneumatic operated butterfly valve and its gate is with rubber gasket at the bottom. Admixture flask of standard capacity is fitted with feeding pump. Cement is fed from SILO to the cement weighing hopper.

Optional Accessories

- Moisture Probe System (In Sand bin & Mixer).

- Silo Accessories like; Dust collector, level indicator, fluidization pad, pressure relief valve etc.

- Blower system for cement / fly ash loading in silo.

Advance Control System

- Fully automatic PLC control system with SCADA for inventory management and different report generation. Any types of faults and errors will be diagnosed by the control system.

- Emergency manual discharge facility

Stationary Concrete Batching Plant

Our concrete paver finisher provides the capacity to produce high volumes of concrete. So, if you are looking for a product that can deliver without changing sites frequently, look no further. Our concrete batch mix plant is equipped with large storage bins and conveyors for weighing. Its design is robustly resistant to harsh conditions. It is a great choice if you are seeking different concrete mix recipes that cater to your needs.

Mobile Concrete Batching Plant

We provide two different versions of mobile concrete mixing plants including a standard size and a mini machine that meets the varying needs of our clients. It transfers and weighs aggregates using compact aggregate feeders and single conveyors. The compact design makes it easy to install with user-friendly software.

Advantages of Our Concrete Batch Mix Plant

Our product offers the following benefits:

Designed using innovative technology

Offers service with no room for error

Guarantees high performance

Extremely reliable

Versatile

High quality

Advantages of Our Concrete Batch Mix Plant

Our product offers the following benefits:

Designed using innovative technology

Offers service with no room for error

Guarantees high performance

High quality

Extremely reliable

Versatile

Installations Around the World

Technical Information

| Plan Type | CMPL 80 | CMPL 120 | CMPL 160 | CMPL 200 | CMPL 250 | CMPL 300 | CMPL 400 |

|---|---|---|---|---|---|---|---|

| Four Bin Feeder capacity (m3) | 8,10,12,15,20,m3 feeding width is up to 650 mm, dosing with frequency contrlling | ||||||

| Collecting Belt Width (mm) Length (mm) | 500 | 600 | 600 | 650 | 850 | 850 | 850 |

| Varies according to the number of silos | |||||||

| Inclined Belt Width (mm)01 | 500 | 600 | 600 | 650 | 850 | 850 | 850 |

| Dryer Diameter (m) Length (m) | 1.60 | 1.80 | 2.00 | 2.20 | 2.40 | 2.40 | 2.70 |

| 7.00 | 8.00 | 8.60 | 9.00 | 9.00 | 10.00 | 12.00 | |

| Sieving MAchine | |||||||

| 4,5,6 Decks | |||||||

| Hot Aggregate Silos Capacities (tons) | |||||||

| 4,5,6 Divisions | |||||||

| 9 | 20 | 20 | 25 | 25 | 30 | 30 | |

| Aggregate Weighing Capacities (kg) | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 |

| Filler Weighing Capacities (kg) | 150 | 200 | 200 | 250 | 300 | 400 | 500 |

| Bitumen Feeding Capacities (kg) | 6 | 6 | 10 | 10 | 15 | 15 | 20 |

| Mixer Capacities (kg) | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 |

| Automation | |||||||

| Coninfra Automation System | |||||||

| Bitumen – Fuel Tank Capacities (m3) | |||||||

| 20, 25, 30, 50, 60 | |||||||

| Thermal Oil System *1000 (Kcal/h) | 300 | 500 | 600 | 750 | 1000 | 1000 | 1000 |

| Electrical Heating | |||||||

| For all capacities, can be produced in variable capacities regarding to your requests. | |||||||

Frequently Asked Questions About Our Concrete Batching Plants

Coninfra Machinery Pvt Ltd offers a range of Concrete Batching Plants, including stationary and mobile variants. Our diverse lineup caters to various project scales and requirements. As a trusted provider of Concrete Batching Plants, we ensure high-quality construction equipment for efficient and precise concrete mixing and production.

Coninfra Machinery Pvt Ltd provides comprehensive services for their concrete batching plants. This includes installation, commissioning, operator training, and ongoing technical support. We prioritize customer satisfaction by ensuring smooth plant operation and efficient maintenance.

Coninfra Machinery Pvt Ltd’s concrete batching plants are known for their advanced technology and user-friendly features. These include precise weighing systems, efficient mixing, intuitive control panels, and robust construction. Our plants excel in performance, accuracy, and reliability, making them a preferred choice for various construction projects.

Utilizing Coninfra Machinery Pvt Ltd’s concrete batching plants offers multiple benefits. Expect enhanced productivity, consistent concrete quality, reduced wastage, and precise batching. Our plants are engineered for durability, adhering to international standards and environmental norms.

Quality is a priority at Coninfra Machinery Pvt Ltd. We ensure the quality of our concrete batching plants through rigorous testing of components, adherence to industry standards, and continuous improvement based on feedback and technological advancements.

Our Latest Articles

Urban vs. Rural Road Construction: Key Machinery Differences

WMM Machines: Optimizing Mixing Technology for Superior Aggregate Performance

How to Troubleshoot Frequent Bitumen Sprayer Problems

Reach out to Coninfra to receive innovative solutions for your business

+91 90999 41311

Social media